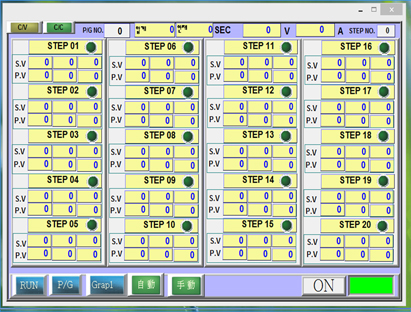

CONTROL METHOD : HMI (Touch screen) & PLC program (102 storage available)

Constant voltage or constant current operation is possible

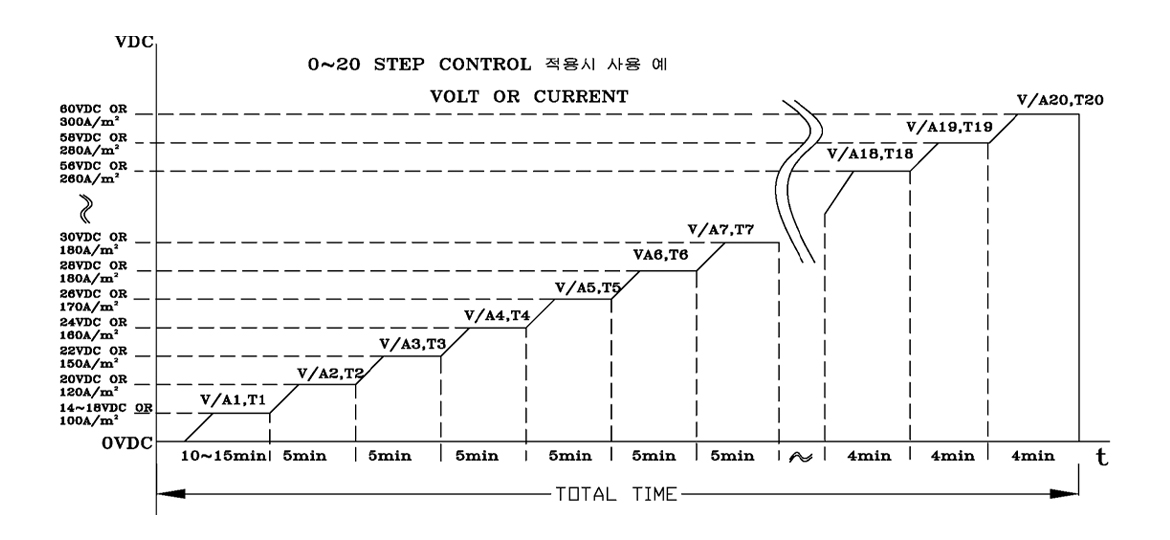

Digital STEP 20 control(Rising, holding, voltage or current value setting)

Precise control from at least 1% point of rectifier capacity

Product-specific programs can be used seperately

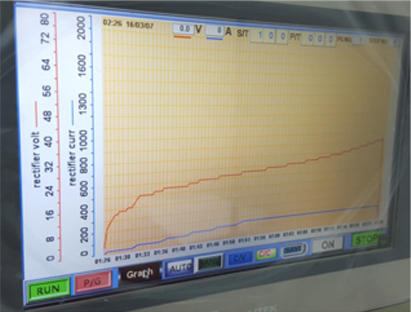

Store rectifier operation date voltage/urrent real time trend (1 year) USB 8GB

Check voltage and current change graph during rectifier operation

COOLING METHOD : air-cooled or oil-cooled

OTHERS : RS-485 communication & precision control method by DCS

Use constant voltage & constant current

Use up to 20 STEP settings ( 102 programs)

Excellent precision with digital control & communication method

Real-time voltage or current change value can be checked visually

Free setting of soft rise time ( 0~999 sec per section)

Skilled technicians are not needed due to using standardized programs / using standardized programs without the need for skilled technicians

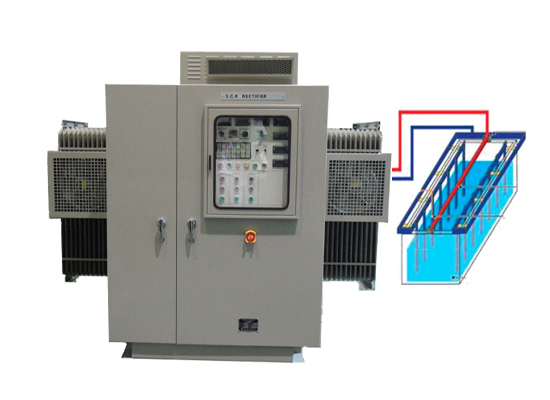

The picture of the left is a stair- controlled rectifier. It is mainly applied to the aluminum hard coating method. Also, Constant voltage, constant current and upto 20 levels of control are possible.

IN PUT :3φ 380V or 440V 60HZ

OUTPUT : 0V ~ 80Vdc/150Vdc/300Vdc 5,000A ~ 18,000A

Control System : HMI & PLC 20STEP/102EA PROGRAM USB Memory V & A electric current trend record

RIPPLE : 5%(max load)

Cooling System : Oil-cooled

Aluminum anodized film electrolytic rectifier

Sulfuric acid : 200~220g/l

Temperature : -5℃ ~ +5℃

Energization time : 50min ~ 150min(35㎛ ~ 60㎛)